Our sister company Mac Environmental Ltd (Mac Enviro) specializes in comprehensive asbestos removal services, delivered with a strong focus on safety, regulatory compliance, and peace of mind. With a professionally structured process and a commitment to best practices, they ensure every project is completed to the highest industry standards.

Initial Inspection and Risk Assessment

- We conduct a thorough site assessment to identify all asbestos-containing materials (ACMs) and determine the most appropriate and safe removal strategy.

Comprehensive Testing and Survey

- All asbestos sampling and analysis are carried out by qualified Asbestos Assessors, with testing conducted in IANZ-accredited laboratories to ensure reliable results.

Notification to WorkSafe New Zealand

- We handle all required notifications to WorkSafe NZ, ensuring full compliance with regulatory obligations before commencing any removal works.

Preparation of Asbestos Removal Control Plan (ARCP)

- Our experienced project managers and supervisors develop site-specific ARCPs to guide each removal project safely and efficiently.

Work Area Preparation

- To prevent contamination, we isolate work zones, implement negative pressure enclosures for Class A removals, and enforce strict access controls.

Safe Asbestos Removal

- Using advanced equipment, appropriate PPE and RPE, our trained professionals safely remove asbestos materials. Asbestos removal involves wet methods and HEPA-filtered tools to minimize airborne fibers.

Air Monitoring and Clearance Testing

- Independent air monitoring is conducted throughout the process to ensure the environment is safe for reoccupation, meeting all regulatory standards.

Decontamination and Waste Disposal

- All asbestos waste is securely double-bagged, labelled, and disposed of at licensed hazardous waste facilities, in full accordance with WorkSafe NZ requirements.

Comprehensive Reporting

- We provide detailed documentation, including the removal methodology, waste tracking, air monitoring results, and clearance certificates for complete project transparency.

More Information about Asbestos

‘Asbestos’ is a term describing naturally occurring fibrous silicate minerals (rock-forming minerals). There are two groups, and six common types:

White asbestos was the most common form of asbestos used in New Zealand, followed by brown asbestos; and blue to a lesser extent.

Under a microscope, white asbestos looks different from brown and blue asbestos.

White asbestos has long, curly fibres, which are flexible enough to spin and weave into fabric. Its versatility made it the most common type of asbestos in building and household products.

Brown asbestos has harsh, spiky fibres. It was mostly mined in Africa and was often used in asbestos cement sheet and pipe insulation. It was also used in insulating board, ceiling tiles and thermal insulation.

Blue asbestos is known for its excellent heat resistance and ability to repel water. It was mostly mined in South Africa, Bolivia and Australia. In South Africa it was called ‘woolly stone.’ It has straight, thin, blue fibres.

Blue asbestos was used to insulate steam engines and is also found in some spray-on coatings, pipe insulation and cement products. It is brittle, and products containing blue asbestos often malfunction. This increases the potential of airborne asbestos exposure for people doing maintenance, repair and replacement work.

Blue asbestos is claimed to be the ‘most dangerous asbestos’ because its fibres are so thin. This makes them easy to inhale and lodge in the linings of a person’s lungs. However, all types of asbestos should be treated with equal caution, because all of their fibres can be inhaled into the lungs.

Class A

Class A asbestos materials are typically considered the most hazardous because they contain a high concentration of asbestos fibers. When disturbed, these fibers can become airborne and be inhaled, leading to serious health conditions such as lung cancer, asbestosis, and mesothelioma.

Class A asbestos is often associated with materials like:

- Sprayed-on fireproofing or insulation.

- Insulation on pipes and boilers.

- Textured coatings.

- Vinyl paper backing.

Class B

Class B asbestos refers to asbestos-containing materials (ACMs) that are considered hazardous but are generally less dangerous than Class A materials. These materials still pose significant health risks, particularly if they are disturbed, as asbestos fibers can become airborne and be inhaled, leading to severe respiratory diseases and cancers.

Class B asbestos materials typically include:

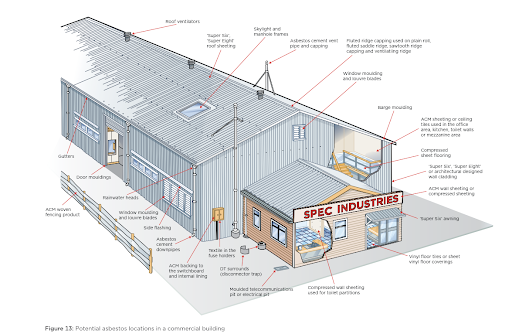

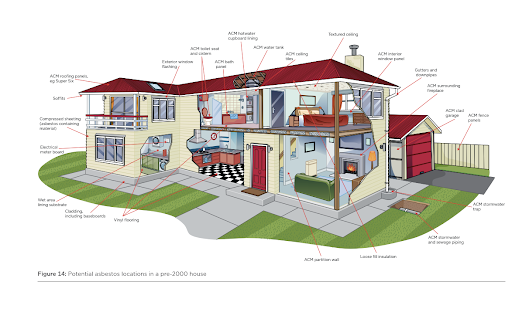

- Asbestos cement cladding.

- Asbestos roofing sheets.

- Asbestos cement pipes.

- Asbestos thermoplastic flooring.