At Mac Group, we specialise in engineered deconstruction and demolition with an engineering-led approach to dismantling structures unlike conventional demolition that often overlooks detailed planning and impact mitigation. Our solutions are thoughtfully designed to safeguard public safety, minimise neighbourhood disruption, and protect the environment.

We are committed to diverting maximum waste from landfills by prioritising reuse, repurpose, and recycling strategies throughout every project.

Proudly recognised for our sustainable efforts, Mac Group recently earned the Eco Choice EC-59-19: Construction & Demolition Waste Services certification.

Mac Group holds an impressive suite of industry certifications, underscoring our dedication to excellence, environmental stewardship, and safety:

- Eco Choice EC-59-19 for Construction & Demolition Waste Services

- ISO 9001 — Quality Management

- ISO 14001 — Environmental Management

- ISO 45001 — Occupational Health & Safety

Our deconstruction and demolition division is equipped and authorised to deliver services for Green Star–rated projects, further aligning our methodologies with sustainable construction standards.

Below are the key steps followed by Mac Group to ensure that the demolition process is both safe and efficient.

Planning and Managing Deconstruction and Demolition Projects

Mac Group ensures that deconstruction and demolition projects are meticulously planned and executed with systems of work that prioritize safety, health, environmental considerations, and efficiency.

Mac Group ensures effective planning, clear communication, and ample time allocation from the initial concept through to the tender and contract execution, ensuring the successful and efficient delivery of every project.

Mac Group ensures that the necessary time for obtaining any required licenses or permits is factored into the project timeline.

Once the contract is awarded, and before work begins, Mac Group define a safe sequence of operations based on a comprehensive risk assessment, tailored to the specific site and conditions.

Mac Group ensures that the sequence of operations serves as the foundation for expanding the deconstruction and demolition methodology for both the tender and the proposed schedule of works. The detailed plan for the tender forms the basis of the deconstruction and demolition methodology for the demolition itself. Mac Group also ensure that the work methods align with the contract requirements for demolition and site clearance, while considering any client-imposed constraints.

Mac Group ensures that sufficient time is allocated for setting up the site before work begins and for executing the demolition tasks effectively.

When planning deconstruction and demolition projects, Mac Group allocate adequate lead-in time to complete all the below necessary activities, ensuring a smooth and efficient process.

Effective site knowledge

Mac Group ensures that a thorough assessment and survey of the site is planned to identify the following, as far as possible:

- The extent of decommissioning required.

- Details of the isolation or removal of services, along with information on temporary supplies.

- Comprehensive knowledge and history of the structure, including its form, materials of construction, structural interactions, and location.

- Isolation and protection measures for adjacent structures.

- Identification of hazardous materials such as Asbestos.

- Previous uses of the site.

Complying with Legal Requirements

LEGISLATION

At Mac Group, we ensure that arrangements are in place to guarantee full compliance with legislation across a range of related fields, including:

- Waste management.

- Reuse, repurpose and recycling.

- Control and minimization of nuisances to the site’s neighbours, including (dust, noise, vibration, smoke, traffic movements and management).

- Air overpressure (Air Overpressure refers to the phenomenon of a sudden increase in air pressure, often caused by activities like blasting, demolition, or the use of heavy machinery. This pressure wave can travel through the air and can have significant effects if not controlled properly. In many cases, air overpressure can be harmful to the surrounding environment, structures, and people if the levels exceed safe limits).

- Environmental protection, including prevention of pollution.

- Occupational health and safety.

- Planning (including listed buildings and party wall constraints).

- Building regulations.

- Highways and roads.

PERMISSIONS, CONSENTS AND LICENSES

Mac Group will emphasize the importance of early consideration regarding whether any permissions, consents, permits, or licenses are required for the works. Additionally, we will assess if any special measures need to be implemented, particularly for works on dangerous structures, special sites (such as asbestos contaminated sites), and any projects that could:

- Affect a public or private road or highway, e.g. works which necessitate:

- The partial or total closure of the road or highway.

- The erection of temporary structures (e.g. scaffolds, fans, screens, hoardings and supports) on or over the road or highway.

- The use of plant or equipment on or over the road or highway; and

- The storage of site vehicles on the road or highway.

- Affect features outside the curtilage of the site (e.g. footway lights, vaults and other voids under a highway).

- Affect access routes, for example, to:

- An adjoining property; or

- Utilities.

- Involve scaffolding or a crane jib passing over an adjoining property; or

Structural Stability

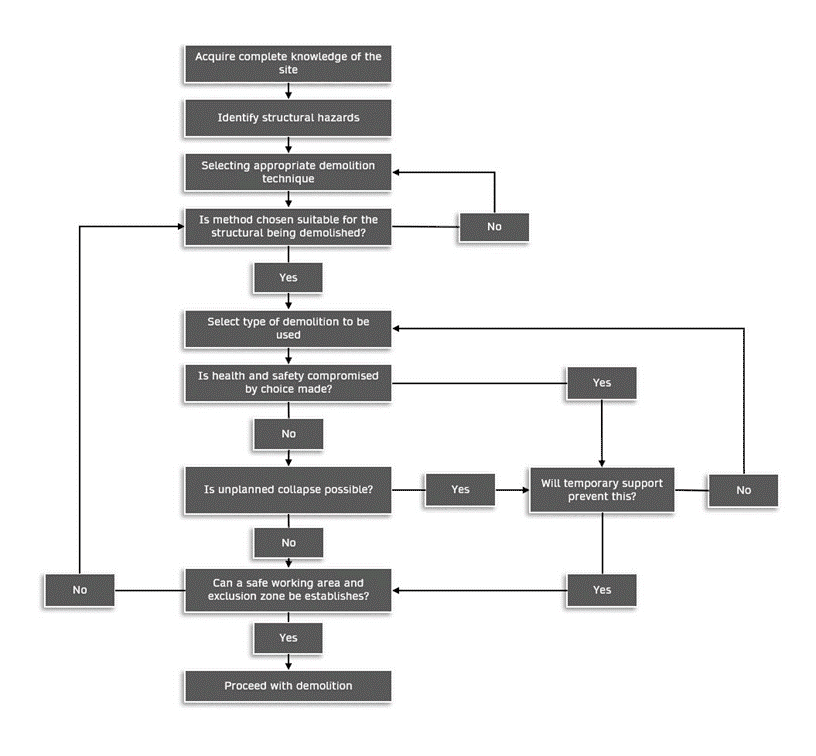

The process for maintaining structural stability should be in accordance with Figure 1, taking the following into consideration.

- Avoidance of unplanned, including premature, collapses and maintenance of residual structural stability.

- Details of any pre-weakening and knowledge of the remaining structural stability designed by a competent engineer, including the sequence of the operation.

- Details of any auxiliary or temporary works to provide support designed by a competent engineer, taking into account adjacent structures.

- Previous collapse history relating to the form of the structure, e.g., large panel precast concrete construction and lift-slab concrete structures.

Flowchart for maintaining structural stability (Figure 1)

Protecting the Public

Mac Group will do arrangements for protecting members of the public should include the following.

- Site security, including the provision of, for example, suitable fencing and/or barriers.

- The control of spectators and/or site visitors.

- Exclusion zones outside the site boundaries during critical aspects of the work, when appropriate.

- Containment of demolition materials.

Environmental Management

The need for the following should be assessed during the planning process.

- Control of noise at the site boundaries.

- Control of dust emissions.

- Waste management, including reduction, reuse and recycling.

- Minimization of materials haulage.

- Bunding arrangements for storage and dispensing of fuel oils.

- Wheel washing plant and road-cleaning arrangements, where required.

- Skip or truck sheeting arrangements.

- Arrangements for dealing with hazardous materials, e.g. flammable materials, gases, hazardous liquids and asbestos.

- Anticipated values of air overpressure and ground vibration.

- Areas of conservation, including flora and fauna.

- Minimizing landfill.

- Carbon consumption/agenda.

Commercial deconstruction and demolition

Mac Group also specializes in commercial office strip-outs, which involves the careful removal of all non-structural elements from an office or commercial space. This service is often required when preparing a building for renovation, reconfiguration, or for new tenants.

Commercial strip outs include removal of walls (including partition walls), ceilings, and flooring to create an open space or to prepare for a new layout.

Dismantling of fixtures such as cabinetry, furniture, lighting, and office partitions.

Disposal of any non-structural materials that are no longer needed.

In some project the scope includes structural walls, slabs, etc.

Our team has extensive experience handling strip-outs for offices of all sizes, ensuring that every project is completed safely, on time and within the budget.

We are committed to environmentally responsible deconstruction and demolition practices, ensuring that as much material as possible is recycled or repurposed.

Commercial deconstruction and demolition refers to the process of dismantling, removing commercial structures such as office buildings, retail spaces, warehouses, and industrial facilities.

It typically involves a combination of techniques, including mechanical demolition or deconstruction, depending on the building’s size, location, and purpose.

Industrial deconstruction and demolition

Mac Group has a dedicated crew that is highly specialized in industrial demolition.

Our team brings extensive expertise and experience to every project, ensuring safe, efficient, and environmentally responsible demolition of industrial facilities.

From factories and warehouses to power plants and manufacturing plants, we handle each project with the precision and care required for large-scale industrial structures.

Industrial deconstruction and demolition refers to the process of dismantling or demolishing large industrial structures, such as factories, warehouses, manufacturing plants, power plants, or any other facilities used for industrial purposes. This type of demolition requires careful planning, specialized equipment, and adherence to safety and environmental standards.

Residential deconstruction and demolition

Mac Group has a dedicated crew that is highly specialized in residential deconstruction and demolition.

Residential deconstruction and demolition involves the removal or dismantling of residential structures, such as houses, townhouses, or apartment buildings. This type of demolition is typically required when a property is no longer safe to inhabit, is being redeveloped, or needs to be cleared for new construction. It can also be needed for structural renovations or to remove outdated or damaged homes.

The most common method used in residential demolition is involving the use of excavators, and other heavy machinery to break down the structure.