Mechanical and Hydraulic maintenance

Mac Group’s Mechanical Maintenance Division delivers expert services across a wide range of industrial sectors, with a strong focus on mechanical and hydraulic maintenance, scheduled shutdowns, and equipment servicing. We provide critical support to manufacturing plants, processing facilities, infrastructure sites, and commercial operations, ensuring that their equipment and systems remain reliable, efficient, and compliant with safety standards.

Our skilled technicians and engineers are experienced in maintaining and repairing mechanical components such as pumps, winches, conveyors, gearboxes, motors, compressors, valves, and hydraulic systems. We specialize in both routine preventative maintenance and responsive breakdown repairs, helping our clients minimize downtime and extend the life of their assets.

We also plan and execute shutdowns and turnarounds, coordinating complex maintenance activities within tight timeframes to ensure a smooth and safe return to operation. Our team works closely with clients to develop detailed shutdown plans, manage resources efficiently, and deliver work to the highest standard—on time and within budget.

With a strong safety culture and deep industry knowledge, our Mechanical Maintenance Division is a trusted partner for both one-off projects and long-term maintenance contracts. Whether it’s ongoing mechanical support or critical shutdown execution, we provide the expertise, tools, and reliability our clients depend on.

As part of our Mechanical Maintenance Division’s capabilities, we successfully completed a significant mechanical and hydraulic refurbishment project on the Wynyard Bridge a vital piece of infrastructure in Auckland’s waterfront precinct.

This complex project involved a comprehensive scope of works, showcasing our technical expertise and commitment to quality.

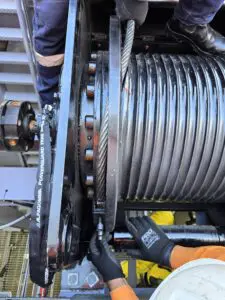

Key components of the refurbishment included the complete overhaul of the winch system, replacement of all wire ropes, and the procurement and installation of a new level wind system to improve operational reliability and safety.

Additionally, our team carried out the refurbishment of the bridge’s pulley system, sliding mechanism, and associated mechanical components, ensuring smooth and consistent performance.

The hydraulic upgrades included the installation of new hydraulic power packs, along with the replacement of locking cylinders to restore full functionality and control.

The project was delivered within tight timeframes and under strict safety and compliance requirements, highlighting our capability to manage high-profile, technically demanding maintenance works on critical infrastructure.

This successful outcome reinforces our reputation as a trusted provider of specialist mechanical and hydraulic maintenance services.

The success of this project was made possible through the collaboration of several key specialist subcontractors.

3D Industrial provided essential machining of mechanical components and refurbishment of other services.

Dana supported the procurement, servicing and integration of key winch components.

Bosch Rexroth supplied and supported the installation of the advanced hydraulic systems.

Shaws contributed their expertise in supplying specially designed wire ropes for the project.

Their technical support, product knowledge, and execution capability were integral to the timely and high-quality delivery of the project. Together, this collaborative effort ensured the Wynyard Bridge was restored to a safe, efficient, and fully operational state reinforcing our capability to lead and manage complex mechanical maintenance projects on critical infrastructure.

We were proud to partner with Highway Electrical, who played a key role in the design and implementation of the control system software. Their team also supplied and installed major components including ABB motors, variable speed drives (VSDs), PLCs, and HMI interfaces, enabling precise and user-friendly control of the bridge’s movement and functionality. Their technical expertise and collaborative approach were essential to the success of the project, and we highly recommend Highway Electrical for their professionalism, reliability, and depth of knowledge in complex infrastructure control systems.